Sciences & Société

Soutenance de thèse : Mathilde EYMANN

Développement de modèles champ complet pour la précipitation et le durcissement structural dans les alliages Al-Sc

Doctorante : Mathilde EYMANN

Laboratoire INSA : MATEIS

École doctorale : ED34 : Matériaux de Lyon

L’allègement des structures dans l’industrie du transport est une étape essentielle pour la transition écologique. Un levier important de cette problématique réside dans l’allègement des matériaux utilisés. Parmi eux, on trouve les alliages à durcissement structural. Leur propriétés mécaniques dépendent fortement de leur microstructure de précipités, aussi il est primordial de pouvoir prédire cet état et son impact sur le durcissement de l’alliage. L’objectif de ce travail de thèse est de construire un modèle numérique en champ complet pour la précipitation, dans lequel les précipités sont décrits par une fonction de forme. Ce modèle se situe entre les modèles de type champ de phase – qui donnent une description détaillée de l’évolution des précipités mais demandent une discrétisation très fine – et les approches champs moyen – très efficaces en terme de temps de calcul, mais reposant sur de fortes hypothèses. ShIFuMo est donc un modèle champ complet, décrivant efficacement les différentes étapes de la précipitation lors d’un traitement thermique isotherme. Des comparaisons avec des modèles champ moyen mettent en lumière les différences entre les deux types d’approches, notamment sur l’importance des interactions solutales et des coagulations au cours de la précipitation. De plus le modèle champ complet présente l’avantage de donner une représentation spatiale des précipités. En effet, l’étude de la fonction de distribution radiale montre l’importance de l’enchaînement des étapes de précipitation sur la microstructure finale, comparée à une microstructure obtenue aléatoirement. Afin de connaître leur impact sur les propriétés mécaniques, les microstructures obtenues avec ShIFuMo sont également utilisées dans un modèle de dynamique des dislocations afin d’étudier les interactions précipités-dislocations. Une comparaison avec les méthodes utilisées en champ moyen montre des différences, mettant en avant l’intérêt d’une modélisation champ complet.

Additional informations

-

Amphithéâtre de la BU Lyon 1 (Villeurbanne)

Recherche

Des bactéries pour recycler les batteries usagées ?

Pour réussir sa transition vers une mobilité décarbonée, la France dépend encore de l’importation de matériaux critiques, comme le lithium et le cobalt. Face à cette dépendance qui sous-tend de nombreux enjeux socio-économiques et écologiques, la recherche d’alternatives pour sécuriser ces ressources se fait urgente.

Parmi l’une des solutions viables : le recyclage des objets riches en métaux grâce à un procédé de biolixiviation. À partir de bactéries, cette technique consiste à faire « digérer » des gisements secondaires, des déchets riches en métaux, par des organismes vivants, pour séparer les composés. Si la création d’une filière dédiée pourrait mettre plusieurs décennies à voir le jour, des initiatives sont en cours de développement dans les laboratoires. C’est le cas au laboratoire DEEP1 de l’INSA Lyon, où Bruno Sialve, enseignant-chercheur et Gabrielle Deslandes, doctorante, explorent la voie biologique pour récolter les métaux des batteries en fin de vie de véhicules électriques.

De la nécessité d’une solution durable pour le recyclage des batteries

L’électrification est l’un des leviers qui participent à la transition d’une mobilité décarbonée. Seulement, pour faire rouler des véhicules à faible émission, il faut produire des batteries. Et pour produire des batteries, il faut des éléments particuliers tels que le lithium, le cobalt ou le nickel. Derrière ces éléments se cachent des impacts environnementaux et des enjeux sociaux très lourds : pollution des sols et des eaux, violations des droits de l'homme dans certains pays contrôlant la majeure partie de ces matières et risques géopolitiques majeurs. Dans ce contexte, le recyclage de ces métaux devient donc une priorité pour limiter cette dépendance, et réduire les coûts écologiques de leur extraction. « Par ailleurs, une directive européenne va inciter d’une part à récupérer le lithium dans les batteries usagées (50 % d’ici à la fin de 2027 et 80 % d’ici à la fin de 2031) et d'autre part à inciter les fabricants à utiliser au moins 6% de lithium recyclé dans les nouvelles batteries. Dès 2031, ce règlement s’appliquera aussi à d’autres métaux stratégiques, avec des taux requis de 16 % pour le cobalt, 85 % pour le plomb et 6 % pour le nickel 2, une raison de plus pour accélérer notre capacité à recycler ces objets », met en contexte Bruno Sialve.

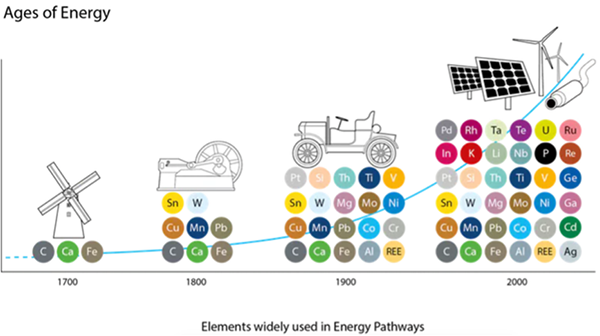

Zepf V, Reller A, Rennie C, Ashfield M & Simmons J, BP (2014): Materials critical to the energy industry.

Différents processus de recyclage déjà à l’épreuve

Plusieurs méthodes de recyclage sont déjà connues et éprouvées. D’abord, la pyrométallurgie qui consiste à fondre les résidus de batteries pour séparer les métaux par fusion. Bien que cette technique soit couramment utilisée, elle est extrêmement énergivore et peu précise, ce qui peut entraîner la perte de certains métaux rares et une grande consommation de ressources. L’hydrométallurgie propose une alternative chimique pour séparer les métaux. Moins gourmande en énergie que sa voisine, elle nécessite tout de même l'usage de produits chimiques potentiellement polluants, impliquant des risques environnementaux élevés et un traitement rigoureux des déchets générés. « Et puis, il existe l’approche biologique, qui emprunte ses grands principes à l’hydrométallurgie : pour produire les acides et reproduire les réactions d’acidolyse, ce sont des populations de bactéries qui remplacent les usines de production de produits chimiques », explique le chercheur du laboratoire DEEP.

Mettre les bactéries au boulot

La biolixiviation, c’est le terme désigné pour ce processus de recyclage par voie biologique, n’est pas nouvelle. À grande échelle, l’activité a vu le jour dans les années 1990, sur le continent africain : solution économique, elle était plus adaptée aux minerais locaux alors difficiles à traiter par des méthodes de lixiviation classiques. « Pour comprendre le mécanisme de la biolixiviation, il faut se représenter des métaux piégés dans une matrice. L’objectif est de les en libérer, en générant un lixiviat enrichi en métaux solubilisés. Pour le produire, on sélectionne des populations microbiennes, selon leurs propriétés connues. Ces organismes vont créer des conditions physico-chimiques précises, pour transformer la matière », indique le chercheur.

Essai de biolixiviation en cours à partir de « black mass », un déchet de batterie (crédits : Bruno Sialve)

Mais pour créer les conditions adéquates à ces écosystèmes complexes, il est nécessaire de les sélectionner et de les adapter. « Il s’agit de « forcer » le microbiote à exprimer des fonctions biologiques données, comme par exemple, oxyder le fer ou produire de l’acide sulfurique. Ensuite, on les met en contact avec nos déchets de batteries, pour observer l’évolution et l’adaptation de la population : est-elle encore vivante ? A-t-elle travaillé efficacement en solubilisant les métaux, etc. ? Et puis, on adapte en fonction des résultats. »

Une fois le jus de métaux généré, plusieurs techniques permettent d’extraire les précieux éléments, pour être à leur tour, réutilisés. « Nos travaux de recherche s’attachent à répondre au premier enjeu du recyclage de ces batteries, c’est-à-dire, séparer les métaux. La biolixiviation est une technique éprouvée par l’industrie minière qui, une fois maîtrisée sur certains types de gisement comme les déchets de batteries de voitures électriques, pourra potentiellement être appliquée à grande échelle, car la filière n’existe pas encore. On pourrait également imaginer l’appliquer à d’autres gisements de déchets riches en métaux ou encore liés à la transition énergétique, comme les éléments de stockage ou les aimants des éoliennes. »

Dans un contexte où la France cherche à renforcer la diversification de ses sources d’approvisionnement en éléments stratégiques, ce processus pourrait ouvrir une voie prometteuse, appliquée à l’échelle industrielle. Au carrefour de l’écologie microbienne et de la biotechnologie, le recyclage par la voie biologique s’intègrerait dans une économie circulaire, limitant la multiplication d’extractions de métaux d’intérêt, et les problématiques environnementales associées.

[1] Déchets Eaux Environnement Pollutions

[2] Source : Règles de durabilité pour les batteries et les déchets de batteries

Sciences & Société

Soutenance de thèse : Antoine LEJEUNE

Étude thermomécanique des émaux sur substrat verrier pour l'industrie automobile

Doctorant : Antoine LEJEUNE

Laboratoire INSA : MatéIS

École doctorale : ED34 : Matériaux de Lyon

Les émaux sont des revêtements inorganiques déposés à la surface du verre dans le but d’apporter une fonction d’opacification au vitrage. Ces revêtements sont des matériaux multi-phasés constitués de fritte de verre, de pigments noirs inorganiques et dans certains cas de charges minérales. Les traitements thermiques appliqués au verre émaillé sont connus pour générer des défauts liés à la présence d’émail : fragilisation mécanique du substrat, genèse de défauts optiques. La compréhension des interactions physico- chimiques entre le substrat verrier et le revêtement d’émail est indispensable afin de limiter ces défauts. Dans ce sens, trois émaux chimiquement différents ont été sélectionnés. La combinaison d’une approche locale et globale des évolutions microstructurales de ces émaux, complémentée par une approche in-situ a été développée. L’analyse a mis en évidence la présence de différents systèmes de fritte verrière, dont un cristallisant en température, à l’origine de l’inhibition du frittage de la couche d’émail. Un protocole de mesure de la contrainte moyenne dans la couche d’émail déposée sur un substrat inerte de silicium a été développé. Cette méthode a montré que l’émail se comportait de manière viscoélastique au-dessus de sa transition vitreuse, au-delà de laquelle la contrainte moyenne dans le revêtement relaxe entièrement. Au refroidissement, les contraintes se régénèrent à une température qui dépend de la fraction volumique de phases rigides, fonction du taux de cristallisation. Ainsi, un réseau percolant se forme et domine l’écoulement visqueux de la matrice vitreuse. Finalement, les interactions chimiques ont été étudiées en déposant l’émail sur substrat verrier. Les résultats ont mis en évidence un échange Li↔Na dont la profondeur dans le verre est proportionnelle à la déformation du verre émaillé à iso-température. Ces travaux ont mis en évidence l’effet des transformations structurales et de la composition chimique de l’émail sur son comportement thermomécanique et rhéologique.

Additional informations

-

Amphithéâtre Emilie du Châtelet (Bibliothèque Marie Curie) - Villeurbanne

Sciences & Société

Soutenance de l'Habilitation à Diriger des Recherches en sciences : Lucile JOLY-POTTUZ

Nanocompression in situ dans un microscope électronique en transmission : développements et étude de la plasticité dans les céramiques

Maître de conférences : Lucile JOLY-POTTUZ

Laboratoire INSA : MatéIS

Rapporteurs : Pr. René Guinebretière, Pr. Hosni Idrissi, Pr. Anne Joulain

Jury :

|

Civilité |

Nom et Prénom |

Grade/Qualité |

Établissement |

|

M |

Guinebretière René |

Professeur des Universités |

Université de Limoges |

|

M |

Idrissi Hosni |

Professeur des Universités |

Université Catholique de Louvain |

|

Mme |

Joulain Anne |

Professeur des Universités |

Université de Poitiers |

|

Mme |

Masenelli-Varlot Karine |

Professeur des Universités |

INSA Lyon |

|

M |

San Miguel Alfonso |

Professeur des Universités |

Université Claude Bernard Lyon 1 |

Additional informations

-

Amphithéâtre CNRS

Sciences & Société

Soutenance de thèse : Sébastien DAGUE

Characterization and modelling of phase transformations and microstructures of cold rolled dual phase steels after heat treatment

Doctorant : Sébastien DAGUE

Laboratoire INSA : MATEIS

École doctorale : ED34 : Matériaux de Lyon

L’objectif de cette thèse était de contribuer au développement et à la compréhension des phénomènes physiques pilotant les évolutions microstructurales d’aciers Dual-Phase, principalement lors des phases de refroidissement. Dans un souci d’utilisation sur des lignes de production industrielles, des outils numériques à champ moyen à base physique ont été développés, ceux-ci étant utilisables pour une large gamme de compositions chimiques et de paramètres du cycle thermique. Une calibration des modèles sur des aciers ternaires issus de coulées de laboratoire a été effectuée avant leur validation sur deux nuances industrielles.

Un modèle, développé dans une thèse antérieure, pour la transformation de phase entre la ferrite et l’austénite ayant lieu lors de la phase de chauffage et maintien isotherme a été modifié avec pour objectif de le rendre plus robuste d’un point de vue numérique.

Un autre modèle visant à simuler la transformation de l’austénite en ferrite, lors de refroidissements lents continus, a été développé. Ce modèle, calibré sur des alliages ternaires Fe-C-Mn, est basé sur une description de la croissance de ferrite faisant intervenir des lois de germination et croissance. Dans un but de rapidité de calcul, ce modèle a été implémenté en langage VBA (Excel). Il a été testé sur différentes compositions d’alliages et il a été possible de trouver des lois de prédiction pour les paramètres du modèle, en fonction de la composition en manganèse de l’alliage et des conditions de refroidissement.

Pour finir, la formation de bainite en condition isotherme à 460°C et 500 °C a été étudiée en DRX in situ sur la ligne DiffAbs du Synchrotron SOLEIL. Le maintien de l’austénite a été mis en évidence lors d’un palier isotherme à 460°C ou à 500°C, pour deux alliages différents. Cette austénite peut ensuite être transformée en martensite lors du refroidissement rapide final, modifiant alors les caractéristiques mécaniques de l’alliage.

Additional informations

-

Amphithéâtre Gaston Berger, INSA-Lyon (Villeurbanne)

Sciences & Société

Soutenance de thèse : Zheheng LIU

Characterization of plastic strain localization in polycrystalline materials by means of 3D X-ray diffraction imaging techniques

Doctorant : Zheheng LIU

Laboratoire INSA : MATEIS

École doctorale : ED34 : Matériaux de Lyon

This thesis is part of the ANR 3DiPolyPlast project devoted to an in-depth study of the mechanisms leading to plastic strain localization in pure metals. 2D surface observations, 3D volume characterization, and numerical simulations are carried out in three simultaneous PhD projects. This thesis focuses on 3D characterization of strain localization using a combination of Topo-Tomography (TT) and Diffraction Contrast Tomography (DCT) - two synchrotron radiation near-field imaging techniques allowing for

1 micron spatial and 0.02-degree angular resolution. Two material systems have been studied: Ti-7Al alloy and pure Ni. In both cases the 6D algorithm is used to reconstruct the orientation field during initial stages of plastic deformation, which in turn is analysed for signatures of strain localization. Both the data acquisition scheme for TT and the 6D / 5D reconstruction algorithms for DCT and TT scans have been optimized. Theoretical analysis for the TT scan is performed to explore the limits of its reconstruction capacities and the methods to enhance them. Simulated diffraction data are used to study joint reconstructions of DCT and TT scans, illustrating possibilities and limitations of the optimized reconstruction framework. Contrary to Ti7Al, exhibiting clearly resolvable orientation contrasts in vicinity of slip bands, the diffraction data from pure Ni could not reveal slip bands, probably due to the weak and diffuse character of slip in this pure material. However, distinct structures in the orientation field were observed in directions perpendicular to the primary slip plane.

Additional informations

-

Salle Auditorium, ESRF the European Synchrotron, 71 Avenue des Martyrs (Grenoble)

Sciences & Société

Soutenance de thèse : Alexandru TECHERES

23/10/2024 à 21h (CEST) / 24/10/2024 à 6h (AEDT)

Doctorant : Alexandru TECHERES

Laboratoire INSA : MATEIS

Ecole doctorale : ED34 : Matériaux de Lyon

The strengthening of Al alloys via Sc and Zr has been well documented in the literature. The formation of L12 Al3Sc and Al3Zr leads to improvements of mechanical properties through formation of precipitates during artificial ageing. However, the scarcity and cost of Sc have always been a challenge towards adoption on an industrial scale. Nonetheless, new mineral deposits discovered in Australia, together with novel processing methods create the expectation that the price of Sc will become more accessible.

In the context of a circular economy, recycling is the norm. However, this introduces impurities in the recycled material which originate from the imperfect sorting of scraps. The precipitation kinetics of Al3Sc in high purity, controlled composition Al alloys is well understood. However, the precipitation process in the presence of impurities such as Fe and Si has not been studied.

Therefore, the problematic of the current thesis focuses of the effect of impurities on the precipitation kinetics in Al-Sc-Zr during artificial ageing at various temperatures. Previous reports in the literature indicate an accelerating effect of Si and there are limited reports on the effect of Fe.

Using a combinatorial method, in this work we investigate the effect of Si on the precipitation kinetics via samples with a macroscopic composition gradient (also called diffusion couples). Additionally, two sets of samples are investigated with different Fe concentration to comparatively study the effect of Fe. The precipitation kinetics is observed indirectly via small angle x-ray scattering (SAXS) and hardness measurements across the samples with macroscopic composition gradient. Furthermore, advanced characterisation techniques such as Scanning Electron Microscopy, Transmission Electron Microscopy and Atom Probe Tomography are employed to analyse conditions determined as critical during the ageing.

A strong acceleration effect was observed, with increased Si, agreeing with previous reports. However, a saturation effect was identified, which seems to depend on the ageing temperature. This is discussed as a function of Si-vacancy interaction in the precipitation of Al3Sc. Modelling in a Kampmann-Wagner Numerical framework was performed assuming various numbers of heterogenous nucleation sites. To match experimental results, it was required to increase the diffusion coefficient of Sc in the presence of Si, further highlighting the acceleration effect.

It was identified via TEM and APT that the presence of Si leads to smaller mean radius and larger volume fraction of precipitates, which promote larger increments of the mechanical properties. Furthermore, it was observed that Si replaces Al in the structure of the precipitates and that the concentration of Si in the precipitates increases with the concentration in the solid solution.

Finally, it was observed that Fe can replace Al in the precipitates too. Moreover, in the presence of Fe, Si is found in higher concentrations inside the precipitate than when Fe is virtually absent. However, only a minimal difference is observed in terms of hardening between the alloys with different Fe content and only early in the ageing process. Analytical strengthening calculations seem to predict well the hardening in a Fe-free alloy but poorly in the Fe-rich one. This indirectly suggests that Fe has an effect on the precipitation kinetics, but more investigations are needed to fully understand the effect of Fe on precipitation in these alloys.

Additional informations

-

https://deakin.zoom.us/j/83683315974?pwd=v9dIuNeebiCxC8etah5ItcjBK5q6Ue.1 (Waurn Ponds, Australia)

Sciences & Société

Soutenance de thèse : Louis LESAGE

Thermodynamic and kinetic control of liquid metal dealloying for the design of porous metallic powders

Doctorant : Louis LESAGE

Laboratoire INSA : MATEIS

Ecole doctorale : ED34 Matériaux de Lyon

Metallic powders are becoming increasingly widespread due to their use in additive manufacturing processes and as catalytic materials. In this context, it is appealing to develop processes that enable the formation of open porosities in metallic powders to modify their mechanical properties and increase their specific surface area. We propose using liquid metal dealloying (LMD) to create porous powders with modified microstructures and properties. LMD is a novel technique that involves the selective dissolution of an alloying element from a precursor in a liquid metal solvent. This results in the formation of a continuous ligament structure and open porosity in the dealloyed layer.

By mixing precursor and solvent powders and heating them above the melting temperature of the solvent, we successfully dealloyed FeNi and NiCu precursor powders. This process led to either fully porous or partially porous microstructures featuring core- shell morphologies. To better understand the kinetics of the dealloying process and the resulting microstructure, we developed a diffusion model based on thermodynamic principles and successfully compared it with experimental results obtained from NiCu alloys immersed in liquid Ag. Additionally, we used in situ X-ray diffraction to monitor the phase transformations occurring during the dealloying of FeNi particles by Mg. This combination of experimental and simulation work demonstrates how dealloyed structures are controlled by equilibrium thermodynamics and/or the kinetics of the dealloying reaction. Our results highlight the potential of LMD to design dealloyed powders with tailored dealloyed fractions, ligament sizes, compositions, and microstructures. Finally, we propose using compression tests applied to powders to assess their suitability for applications in cold spray.

Additional informations

-

Amphithéâtre de BU, Lyon 1 (Villeurbanne)

Sciences & Société

Soutenance de thèse : Hugo GIRARD

Characterization of the fiber-matrix interface fracture properties in long fiber composites

Doctorant : Hugo GIRARD

Laboratoire INSA : MATEIS

École doctorale : ED34 : Matériaux de Lyon

Fiber-matrix interface in long fiber composite is a key aspect of global composite mechanical properties since it drives damage initiation and load transfer. Fiber-matrix interface debonding is usually the first type of damage that occurs when the composite is subjected to transverse loading. After initiation, the interface debonding propagates and often kinks into the matrix, leading to further critical defects for the structure. As a result, it is crucial to accurately characterize the fiber-matrix interface in order to prevent or control damage in composites. Going beyond existing experimental methods currently focused on interface shear fracture properties, single-fiber microcomposite tensile sample loaded transversely are developed to simultaneously characterize opening and shear fracture properties. An accurate experimental characterization of the fiber-matrix debonding process allowed the identification of the interface fracture properties using adequate 2D and 3D numerical approaches and related fracture models such as the Coupled Criterion (CC) and Cohesive Zone Models (CZM). Both the CC and the CZM are able to reproduce the experimentally observed debonding process in 2D, the 3D model being able to describe the free surface singularity. In 3D, the fracture property identification yields tensile strengths and critical energy release rates respectively slightly higher and in the same order of magnitude than those identified in 2D. The 3D model does not enable identifying the shear fracture properties, unlike in 2D. In 2D the optimal initiation crack shapes correspond to i) the stress isocontours for small brittleness numbers, ii) the energy-based shapes for large brittleness numbers and iii) neither of them for intermediate brittleness numbers. The 2D stress isocontours-based debonding shapes provide an accurate estimate of the initiation loading. In 3D, the optimum initiation crack always corresponds to energy-based debonding shapes and the 3D stress isocontours-based debonding shapes may thus overestimate the initiation loading by up to 30%.

Additional informations

-

Amphithéâtre Gaston Berger, INSA-Lyon (Villeurbanne)

Sciences & Société

Soutenance de thèse : Junxiong WANG

Molecular dynamics simulation of semicrystalline polymers: from molecular topology to mechanical properties

Doctorant : Junxiong WANG

Laboratoire INSA : MateiS

École doctorale : ED34 : Matériaux de Lyon

Semi-crystalline polymers have attracted widespread attention due to their wide range of industrial applications, attractive mechanical properties, and good chemical resistance. Semi-crystalline polymers exhibit excellent mechanical properties due to their unique molecular structure (crystalline and amorphous phases overlapping each other). Topological molecules, like ties, loops, … and entanglements in amorphous phase, serve as stress transmitters and can be crucial to mechanical properties. However, these microstructures cannot be studied quantitatively experimentally, and the nonequilibrium process of crystallization and how the microstructure affects mechanical properties cannot be studied at the nanoscale. The dependence of the mechanical properties of semi-crystalline polymers on topology and entanglement has been explored using a coarse-grained model through molecular dynamics simulations. From cooling a melt, and after isothermal treatment, semi-crystalline polymers with lamellar structures were obtained with different entanglement densities and topologies. The strongest mechanical properties are shown when the tensile direction is highly consistent with the crystal chain orientation. And the system with a higher entanglement density has a smaller yield stress but a significant stress-hardening regime, indicating that high entanglement density effectively increases the stress-hardening effect. Additionally, the effect of different topologies on mechanical properties has been explored. Uniaxial tensile test results show that cilia have little effect on mechanical properties. The yield stress increases with the number of loops, showing that not only the loops but also the number of topologies has a strong influence on the mechanical properties. The tie molecules appear to have a slightly greater impact on the mechanical properties than the loops, manifesting in a slight strain softening effect. These results will enhance the understanding of the relationship between microstructure and mechanical properties of semicrystalline polymers.

Additional informations

-

Amphithéâtre Emilie du Châtelet (Bibliothèque Marie Curie) - Villeurbanne